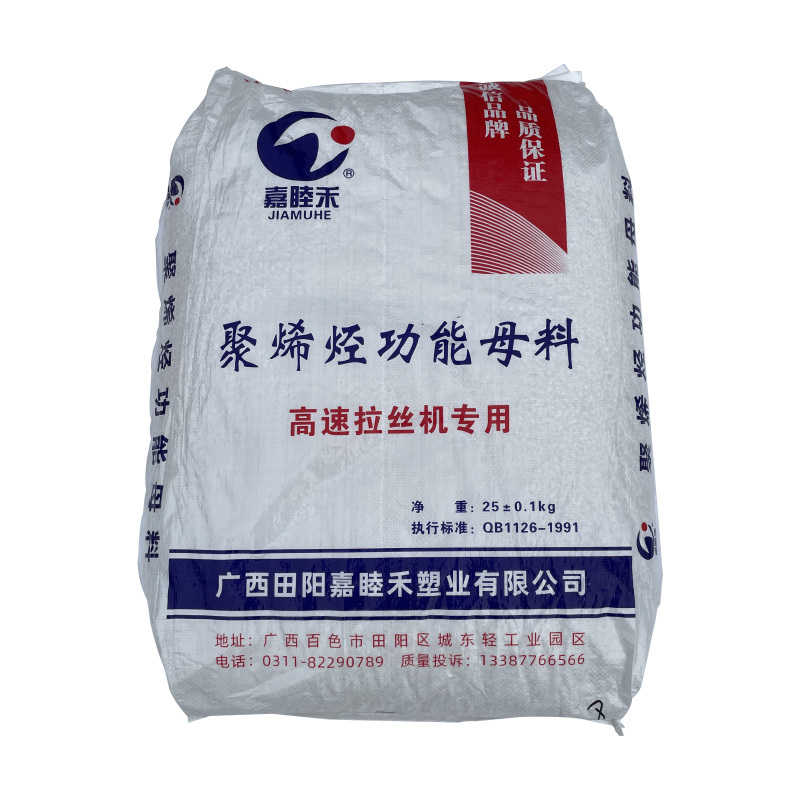

Film coating masterbatch

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Detailed description

-

Based on the process requirements of plastic weaving production enterprises and the performance characteristics of PP flat wire, our company has independently developed advantages such as large filling volume, superior processing performance, good product color and glossiness, and good compatibility with collective resin, greatly improving the production environment of plastic weaving enterprises and greatly reducing production costs. LS-12 has a linear speed of 500 meters per minute, less powder shedding, less smoke, high tensile strength, high brightness, good dispersion, good whiteness, improving product performance and reducing costs.

Product introduction

The coating masterbatch is a product developed and produced by our company using advanced fully automatic mixing and extrusion production lines according to market demand.

Product advantages

Low heat shrinkage, good dispersibility, does not affect adhesion rate, uniform thickness without pores, no water streaks, and does not affect peel strength. The product has good glossiness and does not affect the replacement of the filter screen, greatly reducing production costs and improving customers' competitiveness in the finished product market.

Scope of application

Suitable for paper plastic composite coating, woven bags, ton bags, anti rust packaging bag products, etc.

Usage and dosage

The general addition amount is 10% -30%.

Customer case

Domestic coating machine (Bond, double film head) with a temperature range of 275-283 degrees, 100 mesh filter screen, manual feeding, production speed of 200 meters per minute

Imported coating machine (Stellenger, single film head) with a temperature range of 295-308 degrees, a filter mesh of 260 mesh, automatic feeding, and a production speed of 255 meters per minute. Coating weight: 14-17 grams per square meter.

Domestic coating machine (Youte single film head) 300-350 degrees, filter screen: 100 mesh, manual feeding, production speed: 150 meters/minute.

Note: Proportion of masterbatch added product details:

Valve pocket: 15% -20% Cement bag: 20% -30% Container bag: 10% -15% Color printed bag: 5% -8%

Company Profile

Guangxi Xijin New Materials Co., Ltd. is one of the largest manufacturers of filling masterbatch in South China, focusing on the field of functional filling masterbatch. We have introduced multiple domestically leading three screw extruders, fully automatic environmentally friendly cold and hot mixers, and various environmental protection equipment. Our first-class R&D team continuously develops industry-leading products with a professional spirit and pragmatic attitude.

With over 20 years of production and research and development experience, we can customize products according to customer requirements.

According to the process requirements of plastic weaving production enterprises, combined with the performance characteristics of PP flat wire, our company has independently developed advantages such as large filling amount, superior processing performance, good product color and glossiness, and good compatibility with collective resin, greatly improving the production environment of plastic weaving enterprises and greatly reducing production costs. The line speed of LS-12 can reach 500 meters per minute, with less powder shedding, less smoke, high tensile strength, high brightness, better dispersibility, better whiteness, improving product performance, and reducing costs. It is an ideal multifunctional modified masterbatch for plastic weaving enterprises.

Honor

Factory

Group Photo

Film coating masterbatch

Still deciding? Get samples first, Contact US !

Products Category

Keywords

Related Products